Once more I'm in debt to the guys over at Railwire, Not only do they put up with my rather verbose threads, they offer comments and suggestions that help me formulate some of ideas you see on these pages. By talking the spline roadbed through with them I came up with better ways to build it, strengthen it and keep the cost down.

Experimentation on the roadbed has exhausted itself. I started out planning to use laminated extruded foam splines that might support 20 - 25 lbs over a 12" span. The roadbed actually being used is still spline, but it's now reinforced and can carry about three or four times the load. Just about every method I used on the "test" spline has been revised.

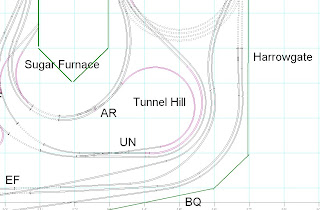

I had planned to start west from Llyswen Yards towards Tunnel Hill. I decided for several reasons to change that and start from the "east" at Harrowgate at the bottom of the helix. The roadbed is much shorter here. I could try out the new construction methods over a relatively limited space before committing myself to the climb up The Hill. I also think Harrowgate will be one of the most interesting scenic features...

|

| Harrowgate Track Arrangment |

There are two types of roadbed required here. The westbound mainline is double tracked through the entire scene. It crosses the Juniata River twice in less that 60" and dives into a tunnel through Short Mountain. The eastbound tracks are also double tracked, but only for a short distance. They both run out of the tunnels and along the opposite bank of the river, but Track 4 separates and begins its vertical climb to the flyover at EF. Tracks 3 and 4 use single track roadbed.

Using the hard strips of laminate I mocked up the track arrangement before I start assembling the splines. This allows me to see the relative positions of the tracks, including the curves. Think of it as making a model of the layout before you actually build it, but in the actual scale, not as a smaller miniature...

|

| Harrowgate Mockup |

Here at Harrowgate I'm going to start with the tracks closest to the aisle, Track 1 and 2. I cut a foam strip so I get a section about 3 or 4 feet long. Using this short piece will stagger the joints. I run a bead of glue along the foam and spread the glue out evenly with a 1" brush. I keep the brush in soapy water so when I use it the glue thins a little and makes a sort of soup. I try to cover the entire side. I want the lamination to be solid. When you are using the laminate any space without glue means a void that can grow and erode the integrity of the spline...

I left the laminatestrip from the mockup standing right where it was. I stand the new foam strip next to the hard strip and start clamping them together using conventional (but cheap) clamps. I then wait a few minute for the glue to set up. Tacky glue gets, well, tacky in just a few minutes. Tacky enough to hold the two pieces together and allow me to use the clamps somewhere else, like further down the spline...

|

| Clamped and waiting for the glue to set |

|

| Work along the spline, adjusting and clamping |

The spline I'm creating is only 15 feet long, so I continue the first course all the way from Harrowgate to the foam slab at East Keystone. I then go back to Harrowgate and start on the second course. This time I start with a full 8 foot foam strip. I glue it up and stand it next to the first. Although I'll use conventional clamps to get started, I begin using my disposable clamps, 1" long coarse thread drywall screws. I use the coarse thread because it holds better. I just push the screw into the foam until the head is flush. I space the screws about 6" apart.

I'm always learning as I do things. As I worked along the spline I learned that by offsetting the screws vertically they did a better job as clamps. So I started putting one low and the other high on 6" centers...

|

| Disposable "Clamps" |

I'm always learning as I do things. As I worked along the spline I learned that by offsetting the screws vertically they did a better job as clamps. So I started putting one low and the other high on 6" centers...

|

| Offsetting the "clamps" |

The rest of the spline is done using the same procedures. each course gets a set of offset drywall crews to help hold it to the previous course. They will be left in the spline to add horizontal strength. As I go along the spline I check previous work for level or strips that might need to be clamped until the glue actually dries. The hard strips of laminate are especially prone to this as they tend to have what's called "memory" or tendency to return to a former state.Clamping until the glue sets up longer usually takes care of this. I don't use drywall screws on the hard strips. The laminate is tough and I would have to drill a pilot hole for each screw.

I know all this sounds like a lot of work but it actually happens faster than you would think. While I did let the first course sit overnight, I did the other three in one afternoon. Then end result of those few hours was a fifteen foot length of two track roadbed using a four course spline...

Once setup the spline is pretty much a permanent shape. It can be picked up as one piece...

|

| Two track roadbed. |

|

| Picked up as one piece |

You'll notice I did not make a provision for the bridges over the Juniata. I hadn't thought of how I would do that until just now. I'm planning to use the spline as part of the bridge. Since the bridges are both Pennsy style stone arch bridges I intend to cut arches into the splines using a hole saw and razor saw...

|

| Spline Bridge |

I've been hanging around with those Railwire people too much. Their inventiveness is contagious.

In other news...

It took a bit of doing but there is now a full size drawing of Llyswen Yards. I went Staples and they couldn't do it. I asked at the forum and they suggested FedX-Kinkos. I resolved to go there first thing this morning. My better half suggested Office Max. Since she has a habit of being right about things, I gave it a try. Two Office Max stores later I ended up at FedX. They tried to do it while I waited, but were having trouble with it. I told them I could come back later if they needed time to fool around with it. After FedX I went to take my wife to the doctors. I told her about my "experience". "You know, you're pretty good at being right, but when you're wrong...You're dead wrong. We both had a good laugh and off we went. While I was waiting for her I got a call form the printer that the job was done. Voila! $36 and some change later...

|

| 3' x 15' Print of Llyswen Yards |

FedX Office or Kinkos or whatever charges $0.75 a square foot for this work and I'm impressed. Unfortunately, after spending almost $40 I sure as hell am not gonna glue it to the foam slab. I'll figure out some "non invasive" way to transfer the image. Then I'm gonna hang this sucker as a permanent exhibit in the layout room/garage. I do to finish the garage and make it all nice and hospitable. This print will hang on the walls with all my other memorabilia. Maybe I'll hang it together with this...

|

| Altoona, 1946 |

No comments:

Post a Comment