The two track spline for the eastbound tracks is complete. The entire structure weighs almost nothing. It's kinda eerie to lift something 15 feet long and find that...

A - It isn't awkward to lift. Grab one end and the whole thing comes up as one piece.

B - There isn't any stress. It doesn't flop, bend or break.

|

| "Hardshell Spline" |

I've started building the rest of the roadbed in this area. As I went I learned more about what and what not to do with these splines. Laminating the hard strips is best done last. The core of foam strips remains very flexible even after lamination. This allows a great degree of adjustment. The hard shell should be added last after any last minute changes. It will stiffen the spline significantly, in effect "freezing" the spline into a permanent shape. The tacky glue works great on the foam, and is one of the reasons it remains flexible. The hard strips require a better adhesive. I'm looking into that.

I'm actually excited, at least as excited as you can be about something like this. It's turning out better than I ever expected. I think this is the permanent solution for the All East (thank God). Looking forward to finishing this up and getting the track down.

I also found that you can actually lay out the entire spline and make changes before committing to the final form. Drywall screws, or pins for that matter, can be used to hold the strips together while the configuration is worked out. I laid out the entire side of the layout between East Keystone and Harrowgate in just a few hours. It's also quit easy to make revisions. I was even able to remove the hard strips and split the spline to correct an error.

The spline I laid out today will be be glued up tomorrow and will be ready the next day for ballast strip and track. I probably won't lay track, but I could if I desired. I'll more likely move on to the west end of Llyswen Yards and start building the roadbed to Tunnel Hill.

The entire layout is now 2" higher than previously. Everything track related is being raised to match the 2" foam slab. I built an elevated base for the helix to bring it to the same level. Fortunately I hadn't finished the helix past the second level or fastened it down. I could move it aside to install the adjusted.base...

|

| Adjusted Helix Base |

|

| Helix Moved Aside |

|

| Bare Benchwork Awaiting Adjusted Base |

|

| New Plywood for Helix Base |

|

| Glue Setting On New 1" Foam |

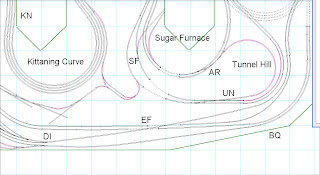

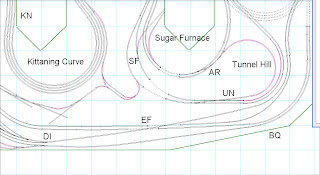

The roadbed on east side of the Allegheny Eastern is ready to be assembled. I used the foam strips to lay out all the track as it appeared on the track plan. The spline allows me to make changes on the fly. It's easy to cut and adjust. I'm building west from Harrowgate to East Keystone...

|

| Area Under Construction |

|

| Harrowgate Looking West Toward Curved Arch Bridge |

|

| Curved Arch Bridge Looking West toward BQ Tower |

|

| BQ Tower Looking West Toward EF, DI, and East Keystone |

|

| Aerial View, Looking West to Flyover at EF Tower |

|

| EF Tower Looking West Towards DI and Llyswen |

|

| Aerial View Looking West Towards Llyswen Yards |

|

| DI Tower Looking East Towards EF and BQ |

|

| Overall View From East Keystone Towards Harrowgate |

I used conventional clamps and drywall screws to hold the foam together temporarily. I also used a new method for gutting the laminate. If I hold the utility knife as you might an aircraft joystick I get better control and more pressure. With this grip using the back of the blade on the smooth side is pretty effective...

|

| "Backhanded" Cutting |

I also dug up an old fishing knife of my Dad's to use for separating the laminations when necessary. I had to rework the two track spline I built yesterday. It's supposed to split at BQ and I ran both tracks to East Keystone. It worked great...

|

| "Delaminator" Removing Hard Strip |

|

| "Delminator" Splitting Spline |

One last comment...I worked on laying the full size print over the foam slab at Llyswen Yards. That area is now the most expensive real estate on the All East. It cost about $70 for the foam and the print. I don't want to think how much all that track is gonna cost....

|

| Llyswen Yards |

Regards

Frank Musick

Chief Cook and Bottle Washer

|

| Allegheny Eastern Railroad |

No comments:

Post a Comment