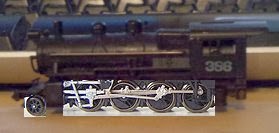

Still looking into kitbashing an H class 2-8-0. Found out that Kato makes a model of a Japanese 9600 class Consolidation. For me it's wiser to buy the drive from the parts department rather than cannabalize a perfectly good locomotive. I checked the Kato Japan parts site, but no 9600 drives are available. Kato Japan seems to stock parts on a random basis so I'll keep looking...

|

| Kato/Trix Bash |

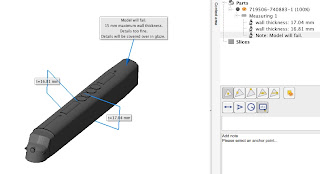

The Centipede project is still on hold. No response from the software publisher. I've thought of buying the newer version of the software but I'm not sure that would solve other technical difficulties I'm having with the model.

Trackwork has started on the layout. Yesterday I laid about fifteen feet of track. Took a while. Keep in mind that this is 15 x 4 or 60 feet of code 55 so the actual progress went better than it sounds. Heading west from Spruce Creek we start with Forge Curve...

|

| Forge Curve From Spruce Creek |

In the real world there is quite a bit of real estate between Spruce Creek and East Altoona, including Tyrone and the junction of several branches...

| Tyrone Today |

On the layout Forge is directly east of Homer, so close that the elevation of Track 2 starts just west of the Spruce Creek tunnels. The separation of the eastbound and westbound mains continues though the curve into Homer...

|

| Forge Curve and the "Ramp" to Homer |

|

| Homer Looking East |

On the prototype the PRR literally created a huge fill and constructed the westbound arrival yard. Homer was at the west end of this yard and the top of the "hump" for the westbound classification yard. There is no way to replicate this arrangement on the Allegheny Eastern (short of changing to Z or T scale). I opted to create the appearance of Homer instead because A - It avoids a complex set of crossovers that would be required other wise and B - I like the way it looks...

|

| Staged Action at the Homer "fly over" |

In the image above an L1 hauls a westbound consist of automobile empties over the "flyover" Atrain hauled by an EF4 (A-B-B-A set of EF15's) heads east on Track 1 as two passenger trains pass on Tracks 2 and 3. It's a staged picture of course, but I couldn't help creating a preview of the finished layout. The trains aren't actually trains, just locomotives and some cars as can be seen in this image of the west side of Homer.

|

| Homer as Seen From the West Side |

I got as far as the yard approaches at East Altoona where the tracks leave the spline roadbed and run on the slab of 2" thick styrofoam.

|

| Tracks 2 and 3 Looking Back From East Altoona |

|

| Tracks 1 and 4 Looking East |

Once again taking photos of progress on a a project helps you see flaws your eyes (and brain) tend to gloss over. Although I'm fairly happy with the linear look of the mains, I can see there are vertical dips I need to correct. They may just be distortions in the picture, but at least I know where to use a straight edge to check things out.

Next I take the rails through Juniata. The challenge will be getting the tracks perfectly straight and parallel for the next fifteen feet. I find the curves can be eyeballed but straight sections are a great deal harder.

Regards,

Frank Musick

Chief Cook and Bottle Washer

|

| Allegheny Eastern Railroad |